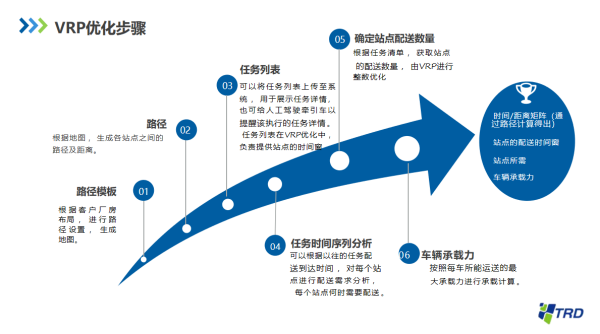

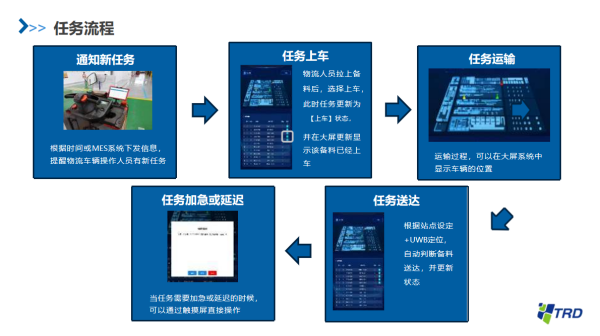

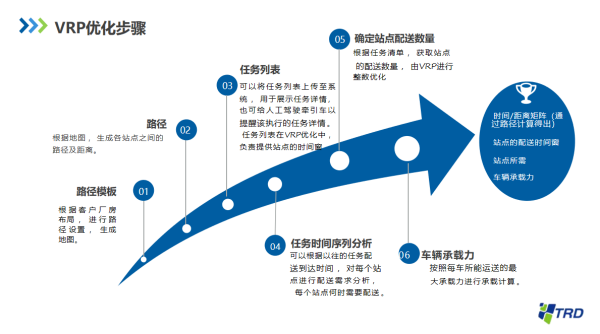

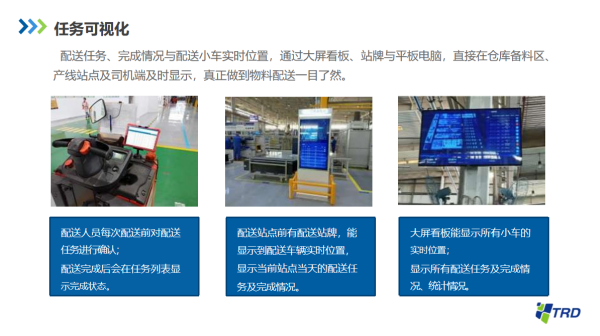

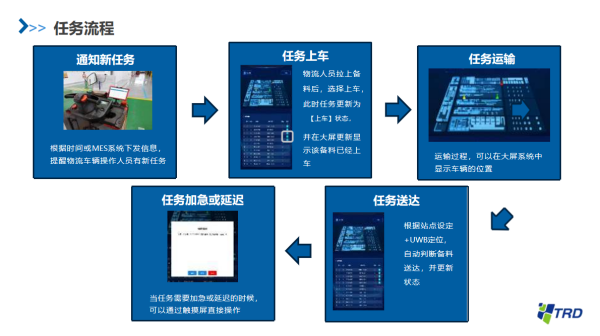

In the complex warehouse working conditions, it has become a difficult problem to achieve efficient management and distribution of production materials. The intelligent distribution management system for production materials developed by Tianjin TRD, a Nooploop solution provider, is based on the VRP algorithm and LinkTrack UWB high-precision positioning system to achieve better management and optimization of logistics and distribution for enterprises. The UWB technology is used to realize the precise positioning of the logistics vehicles in the workshop, and the current material distribution tasks are eliminated according to the logistics vehicles arriving at the station sign according to the distribution schedule, so as to improve production efficiency and reduce manual intervention.

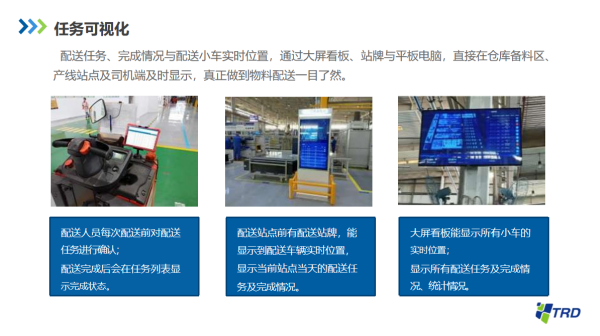

In the project, delivery personnel are able to receive delivery tasks, plan the best delivery route, and view the tractor location in real time. The use of UWB technology (on-site installation of multiple LTP-B base stations, installation of an LTP-B tag on the vehicle) to achieve the precise positioning of the logistics vehicles in the workshop, according to the logistics vehicles according to the distribution schedule to arrive at the station position to eliminate the current material distribution task, so as to improve production efficiency and reduce manual intervention. The system supports docking with the user's MES system or allows the user to upload the timetable, and can be modified at any time to ensure that it is always up to date, and the material distribution system is integrated with the MES/WMS and AVG trolley to achieve digital and intelligent workshop material distribution.