Build a world-class "lighthouse factory" Air cycle ecology helps improve efficiency by 1 million times! Realize the complete unmanned inventory management of production equipment in smart factories IPS indoor positioning

Many equipment in the dust-free production workshop

Digital and intelligent transformation is the key for physical enterprises to achieve lean management, safe production, cost reduction and efficiency increase, and is an inevitable trend of industrial upgrading. As of July 19, 2023, nearly 8,000 digital workshops and smart factories have been built across China. Among them, more than 2,500 have reached the level of maturity level 2 or above of intelligent manufacturing capabilities, basically completed digital transformation, and 209 have become intelligent manufacturing demonstration factories with international advanced level, and after transformation, the product development cycle of these demonstration factories has been shortened by an average of 20.7%, and the production efficiency has increased by an average of 34.8%.

The "Workshop Production Equipment Positioning and Inventory Management System" developed by Nooploop Ecological Partners has achieved full coverage of the precise positioning network of about 11,000 square meters in two production workshops of a well-known mobile phone smart terminal enterprise (there are multiple large load-bearing columns and equipment body occlusion in the working environment) through the deployment of more than 50 positioning base stations, and then real-time positioning of 1,000 production equipment.

The equipment is precisely positioned on every production line

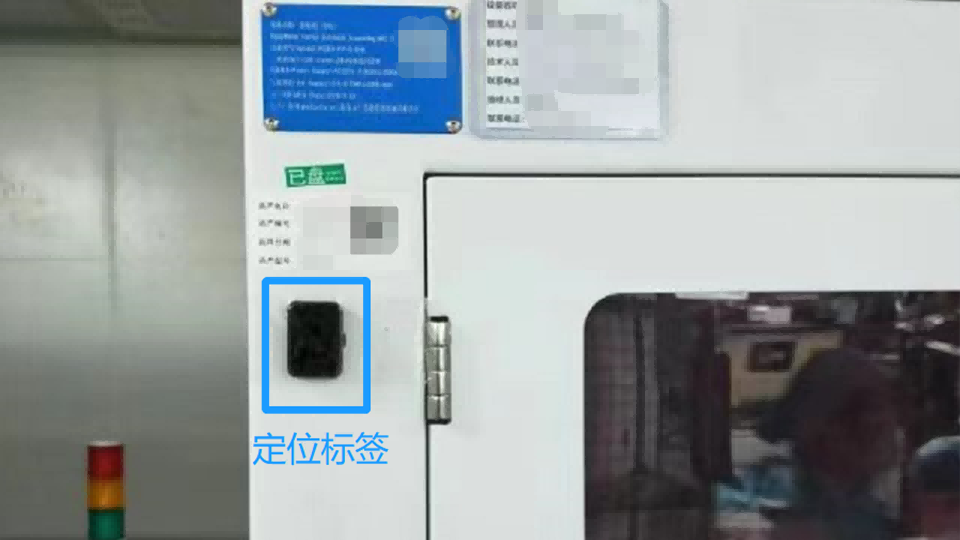

The positioning label is attached to the outer surface of the device

In this enterprise case, there are more than 400 high-value mobile phone production equipment (plate dismantling machine, cutting machine, reflow oven, etc.) in a single workshop, and it is very time-consuming and labor-intensive to make an inventory of these production equipment on a daily basis, and it is easy to miss and misshoot; The equipment is seconded in different workshops, and occasionally the ledger is missed or wrongly recorded. Through the equipment positioning inventory management system, it realizes functions such as one keyboard point, fast device search, and offline alarm

The launch of this system has shortened the inventory time of materials in the workshop from 3 weeks to 10 seconds! A single device location lookup takes less than 5 seconds each time! The overall displacement management of production equipment in the two workshops is completely unmanned. Compared with the previous manual management, the current material inventory management error rate has been reduced by 98%, and the highest honor of the world-class "lighthouse factory" will be affected by this application.