Precise positioning for Industry 4.0 UWB Omlox seminar on-site sharing and positioning experience

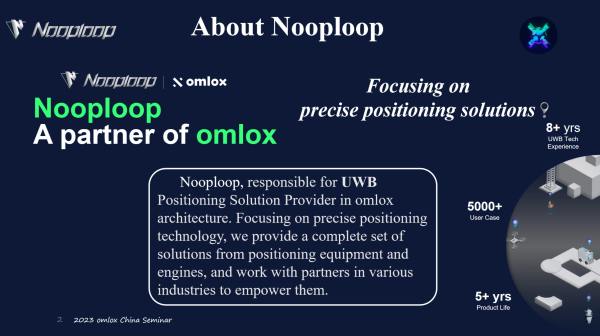

The IPS indoor positioning system includes positioning background, communication network, positioning base station, positioning label equipment, and the positioning background is responsible for solving data and realizing business functions; The communication network is responsible for the exchange of data and information; The positioning base station is also similar to the satellite to achieve reference positioning; Positioning tags are used to track objects to be located.

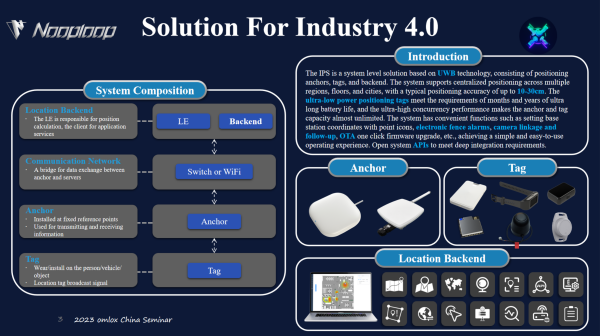

In the process of on-site deployment of the positioning system, 1 base station is deployed in a small room and small area, 2 base stations in a long and narrow area, and 4 base stations in a large area to achieve the optimal deployment of base stations. Fewer base stations, more efficiency!

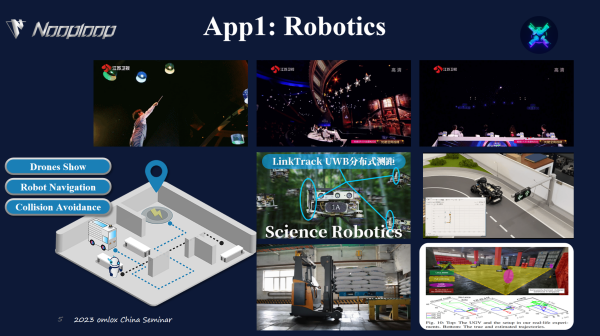

On the road to Industry 4.0 with various ecological partners, Nooploop's precise positioning technology empowers various industries at the same time.

The sports and entertainment scene also flashes the figure of empty circulation, analyzing athlete data in the sports meeting trials, following the actors in the stage lighting show, and realizing human-computer interaction in the new product launch.

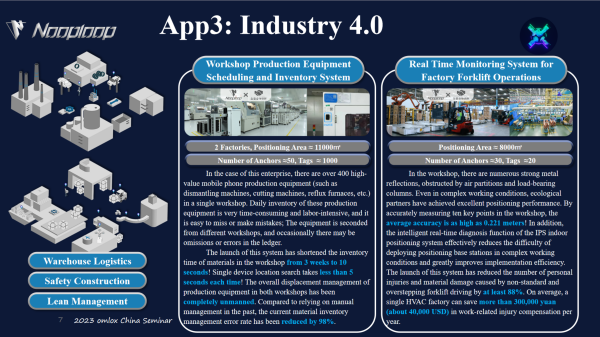

Industry 4.0 has different requirements and challenges. Through the deployment of more than 50 base stations, the workshop production equipment positioning and inventory system developed by Nooploop integrator has achieved accurate positioning and full coverage of a total area of about 11,000 square meters in two production workshops, and then realized the real-time positioning of 1,000 production equipment. The launch of this system has shortened the time taken to count materials from three weeks to 10 seconds; The overall displacement management of production equipment in the two workshops is completely unmanned. Compared with the previous manual management, the error rate of equipment and material inventory has been reduced by 98%. The real-time monitoring system for the location of factory forklifts developed by Nooploop integrators can achieve accurate positioning in an area of 8,000 square meters through the deployment of more than 30 base stations, and then realize the real-time positioning and monitoring of multiple forklifts. In the workshop, there are many strong metal reflections, air compartments and load-bearing columns blocking, even in complex working conditions, through the accuracy measurement of ten key points in the workshop, the average accuracy is as high as 0.221 meters! In addition, the intelligent real-time diagnosis function of the IPS indoor positioning system effectively reduces the difficulty of positioning base station deployment in complex working conditions and greatly improves the implementation efficiency. The launch of the system has reduced the number of personal injuries and material damage caused by irregular forklift driving and crossing the line by at least 88%, and a single HVAC plant can save more than 300,000 yuan in work-related injury compensation on average a year.

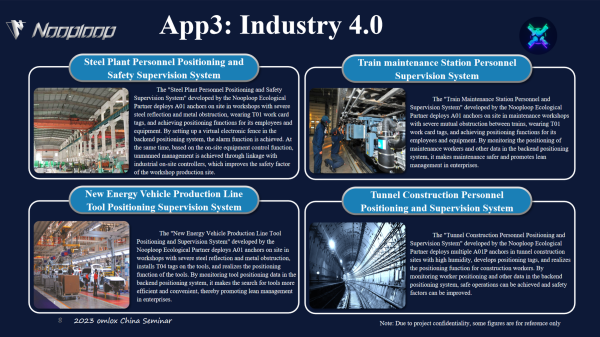

By cooperating with integrators, Nooploop has achieved safety supervision of employee positioning in steel plants, lean management of personnel positioning in train maintenance workshops, efficient scheduling of tool positioning in the final assembly of new energy vehicles, and monitoring of operators in tunnel construction scenarios to improve safety factors.

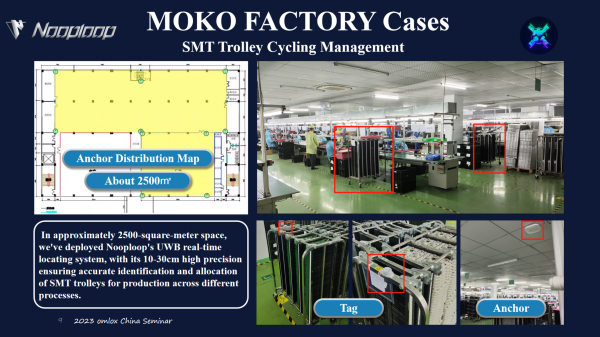

At the same time, Nooploop deployed a precise positioning system in the MOKO SMT factory, covering more than 2,500 square meters, positioning more than 50 SMT circulation vehicles to achieve efficient scheduling and lean management.

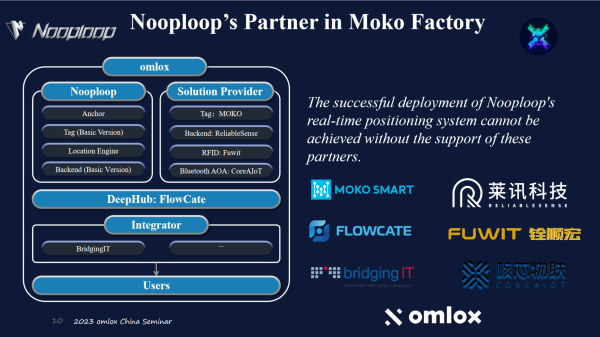

The successful deployment of Nooploop's precise positioning solution at MOKO's factory would not have been possible without the support of various partners, including MOKO Smart, ReliableSense, FlowCate, FUWIT, bridgingIT, CoreAIoT, and the organizer of this year, omlox.

Nooploop is a national high-tech enterprise integrating R&D, production, sales and service, and is committed to providing standard and generalized precision positioning equipment and solutions for various industries around the world. Through precise positioning technology, we work with partners to empower various industries and continue to promote the progress of human society. Since its establishment, the company has served thousands of enterprises, universities and scientific research units around the world, covering smart factories, smart cities, warehousing and logistics, sports and entertainment, intelligent body navigation and other fields.